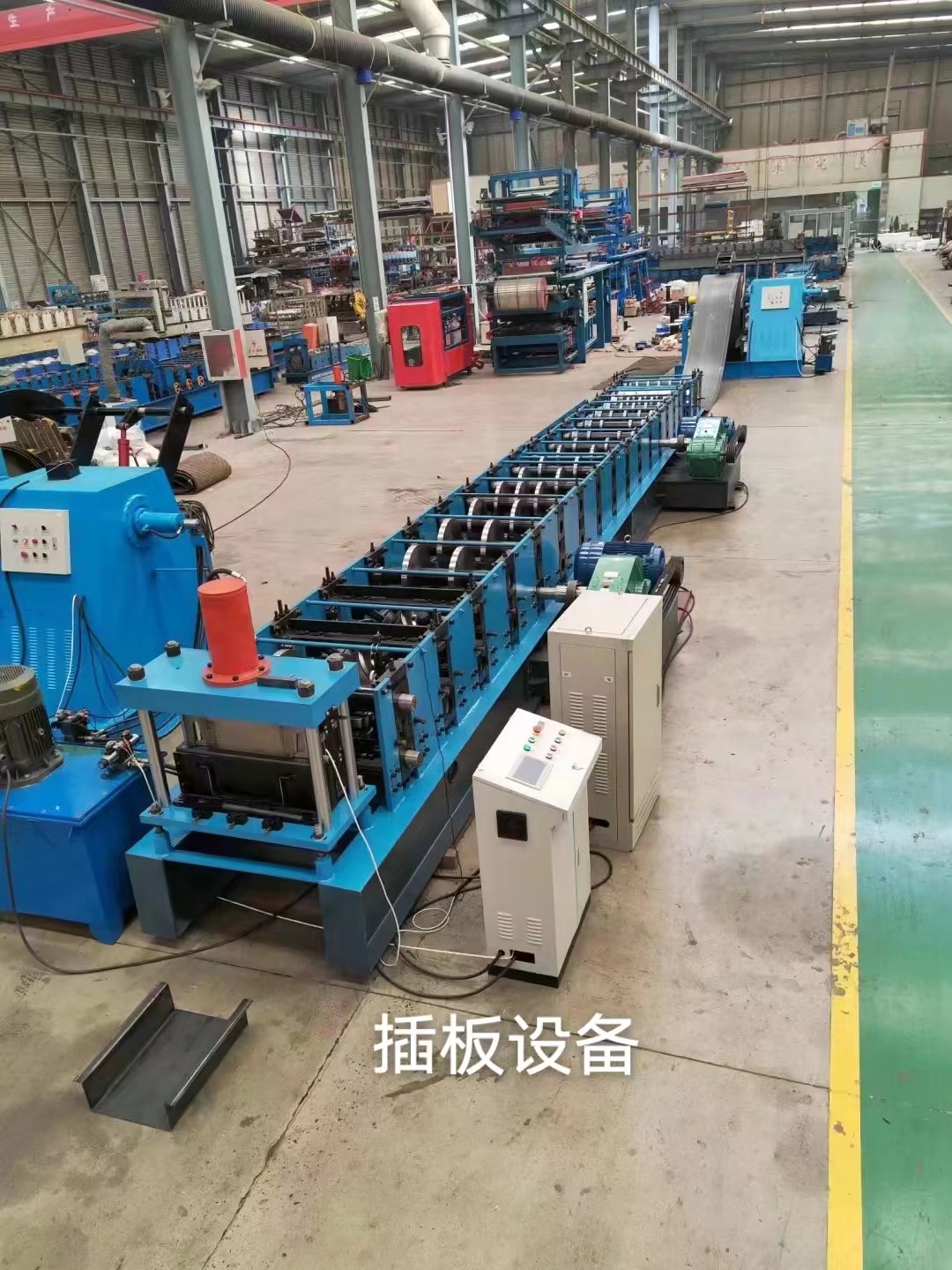

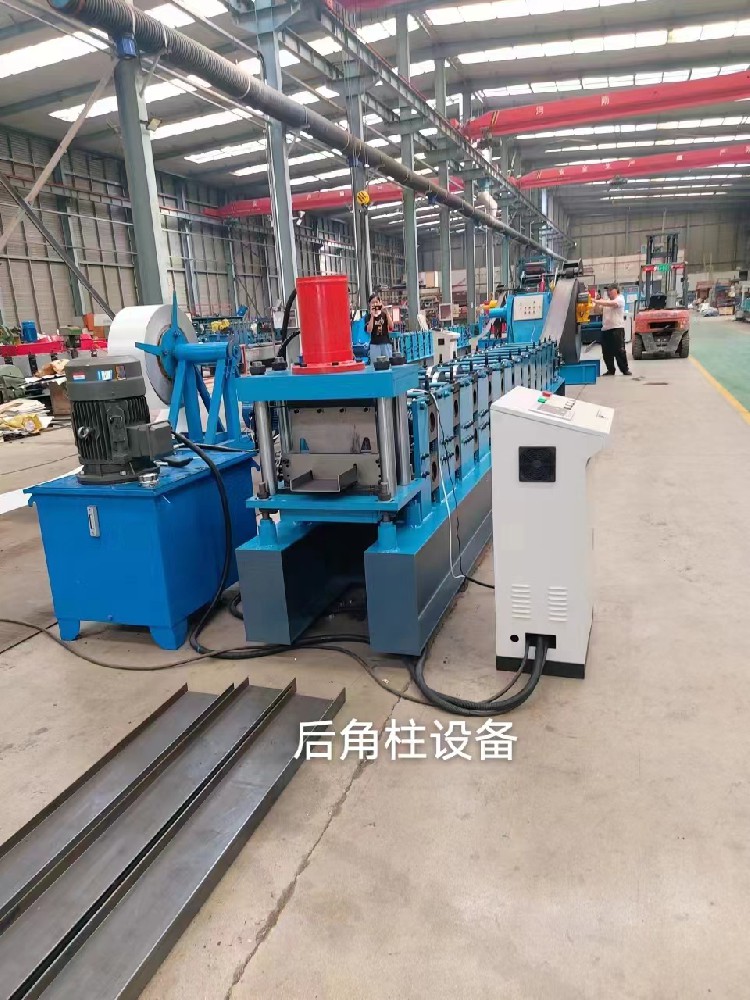

Machine length | 7m | width | 1.8m | height | 1.2m |

power | 18.5Kw | Working voltage | 380V | ||

Working speed | 4-12m/min | ||||

Roller size | 11 steps forming roller diameter105mm Solid roller and material is 45# steel | ||||

Forming roller | Bearing steel forgings, finely turned and polished, with hard chromium plated surface | ||||

Machine base shelf | 400Hprofile steel 20mmthickness plate | ||||

drive | 2inch chain drive | ||||

Cutter power | 7.5Kw pump station | ||||

Cutting saw | Use Cr12material ,It is quenched at high temperature | ||||

Leveling part | It is composed of 7 roll shafts and side wheels, with shaft diameter of 105 | ||||

Press plate | Material 2.0mm thick resistance plate | ||||

Spare pare | One instruction manual and one set of loading rack | ||||

Forming part | The roll forming system is composed of a frame, a transmission part, a cold forming roller group, etc. It is divided into precision wheel rotary molding, which has good molding effect, reduces friction between wheels and raw materials, and is convenient and fast for debugging. | ||||

Working course | (Feeding blank) Uncoiling - guided feeding - roll forming - fixed length cutting - finished product discharging Fix the workpiece manually, roll it up manually, enter the PLC operation page - press the "Start" button - the plate enters automatically - start to follow the set program - cut off automatically after reaching the set size, and the automatic pressing plate forming of the equipment is completed. | ||||

Feeding platform | The left and right guide devices are set at the feeding port of the host machine. During operation, both sides of raw material plates enter the host through left and right guidance to keep the raw material plates and the roll forming system in the correct position. The guide position can be adjusted through the manual screw mechanism and can be adjusted. | ||||

Cutting after forming | The cutting system is composed of cutting frame, cutting die, guide device and cutting oil cylinder. | ||||

Electrical part | It is controlled by Xinjie PLC and adjusted by three crystal frequency converter, which can realize automatic production of the whole machine. Batch, workpiece length, quantity, etc. can be set. Operation mode: input screen+button. Encoder counting, with counting and length recording functions.. | ||||

error | The main machine has many forming rows, stable performance and length error of ± 2mm | ||||

notice | Power supply input: three-phase 380V The distance from the front, back, left and right to the wall and other barriers is more than 1 m | ||||

warranty | 12 months | ||||

Delivery time | 30working days | ||||